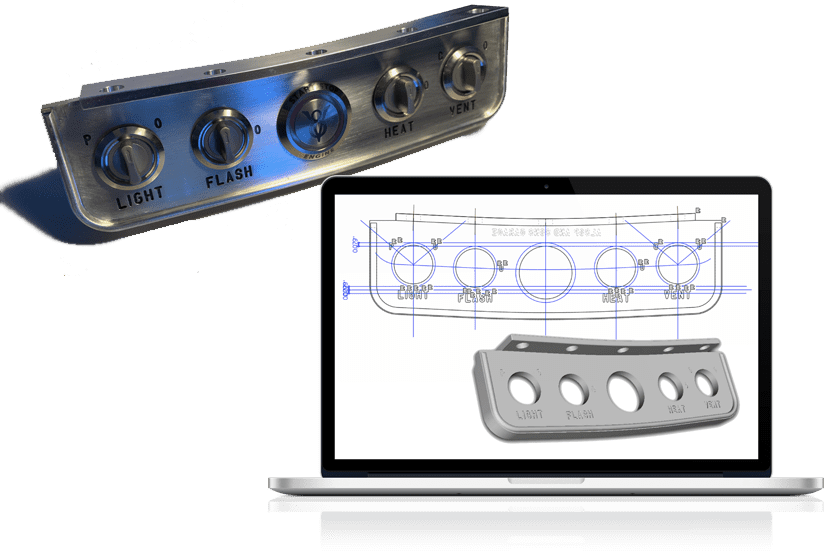

Sometimes you want that perfect piece that no one has. Other times you need to reproduce that impossible to find part. By using 3D Scanning we can create highly accurate scans to be used to develop parts that fit as factory or to reproduce a part with accuracy up to 0.045mm. These parts can be 3D Printed in plastics such as ABS for prototype fitting or for paint and chrome coatings.

Limitless Imagination

Future is Now

Unlock your creative potential and revive the past

There was a time where if you needed a switch, bezel, or some badge and there were no used ones or reproduction ones being made.- you were out of luck. Those days are behind us.

By using 3D Scanning techniques you can scan vintage parts to repliacte them in 3D Printing, CNC milling, or injection molding processes over and over again. You can also scan interior and exterior components to create custom trim panels to fit just as factory and have these printed on 3D Printers.

With this new technology applied to both automotive restoration and customization, the sky is really the limit on what you can create and what you can resurrect. Are you ready to bring 3D technology into your projects?

Our Process to Create Parts

Plan and Scan

We plan out the project together to determine what needs to be 3D scanned.

All projects are different. From scanning and designing a small one-off piece to moving into full production of custom parts. Environment is also important for the best scan possible. Indoors is required and highly reflective surfaces will require a removable paint film or marker dots be applied to scan properly. All of these details are discussed in our initial meetings prior to scanning the part of vehicle.

Design

We design the custom parts with your team or work with your developer using our scans.

This is generally the part of the process that can take some time. We need to take the 3D scanned data and convert it into proper solid objects to build the custom parts from. We then go through the design process with you to get the right custom part design or to ensure a perfect reproduction of a rare original part. We can also work with your 3D developer by supplying them with any scan models they need.

Refine

We work iteratively with you and your team to ensure the best design and fit.

Prior to getting things produced on a CNC mill or creating molds for production, we can create prototype parts on our 3D printer for mockup. These printed parts can be then body worked and refined for a smooth finish and then be used as plugs in the mold making processes.

Build

The final parts are delivered to be used on the car or in the mold making processes.

This is where it gets really fun. The 3D printed parts are deliverd for any finishing processes prior to installation, or for starting a mold making process for more mass production. Having the virtual become reality is always an amazing process and we are always excited to see someone automotive dream come true with this technology!